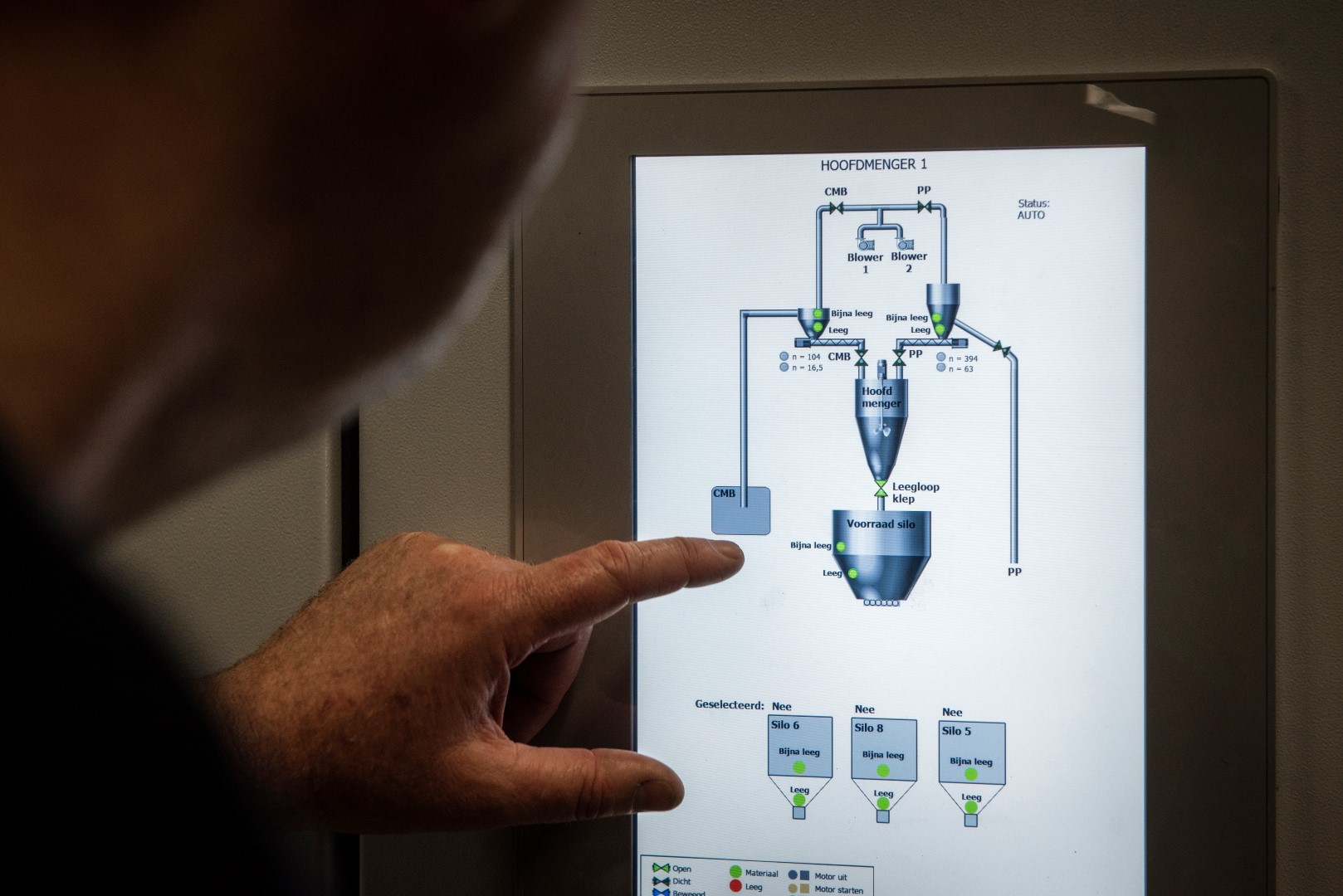

Plastic beads are automatically added to the extrusion systems from the storage silos.

The colourants are added to the beads in every extruder. The hot liquid plastic is extruded and then immediately cooled, causing the plastic to crystallize.

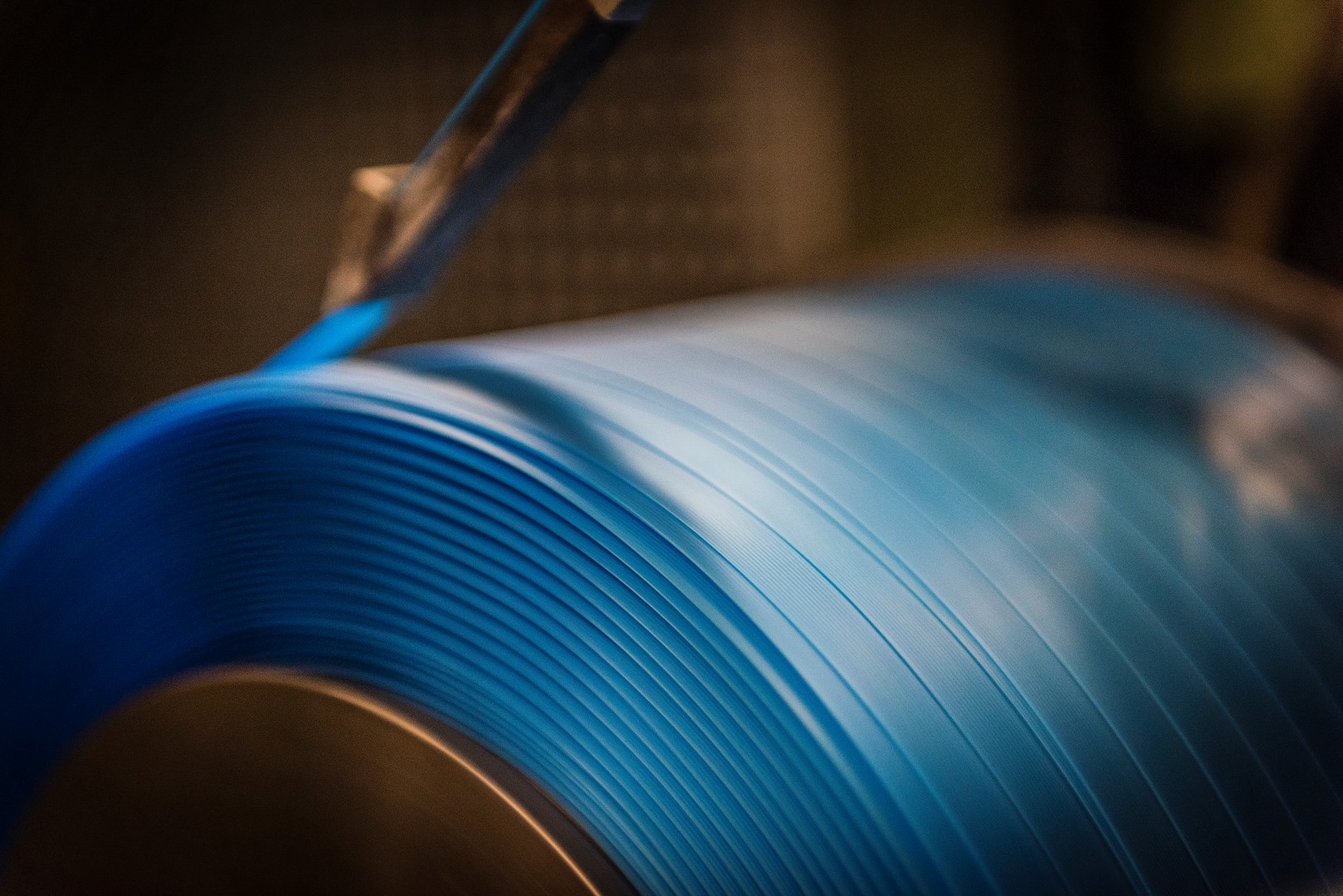

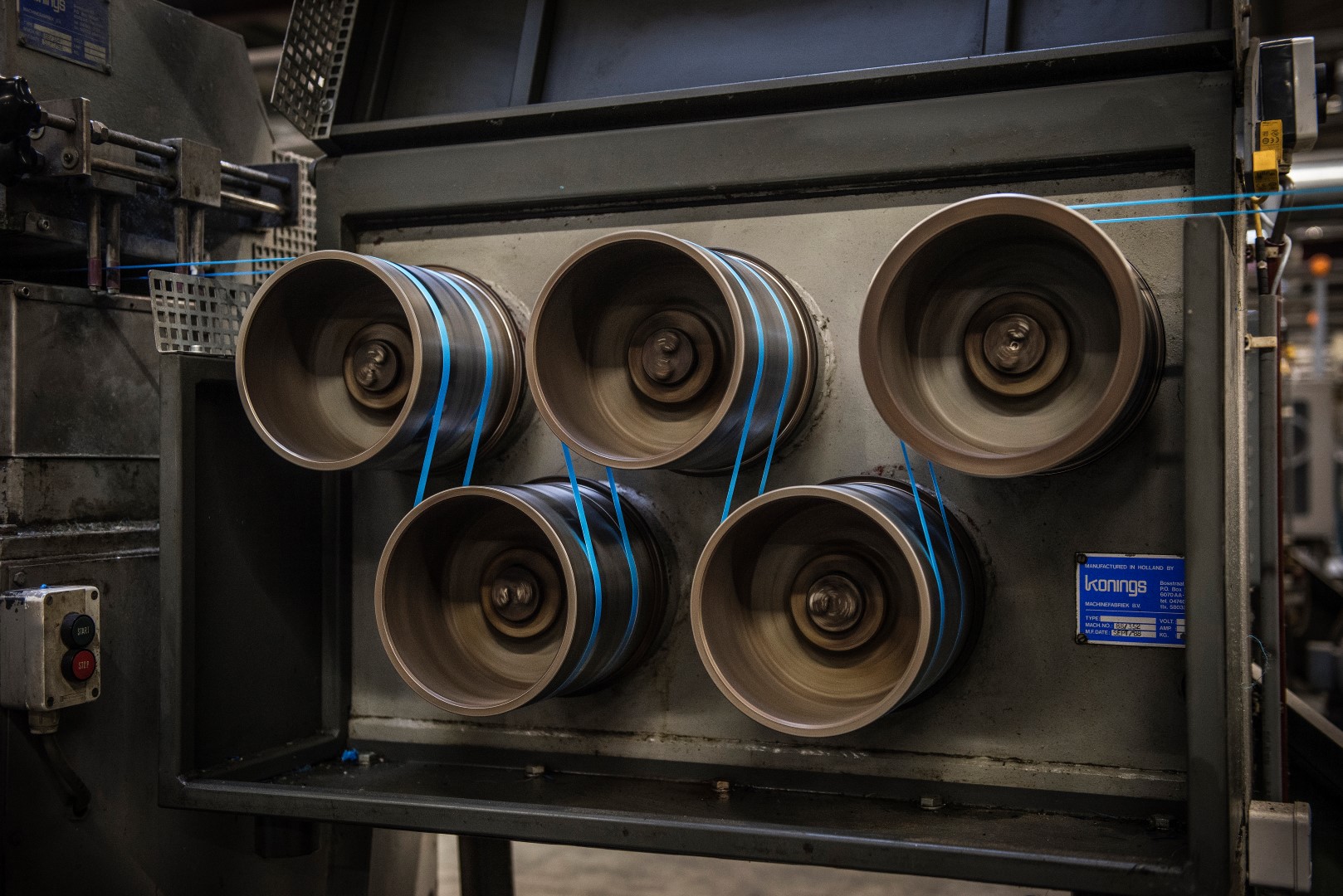

In order to achieve the necessary tensile strength, the tension on the strapping is then increased.

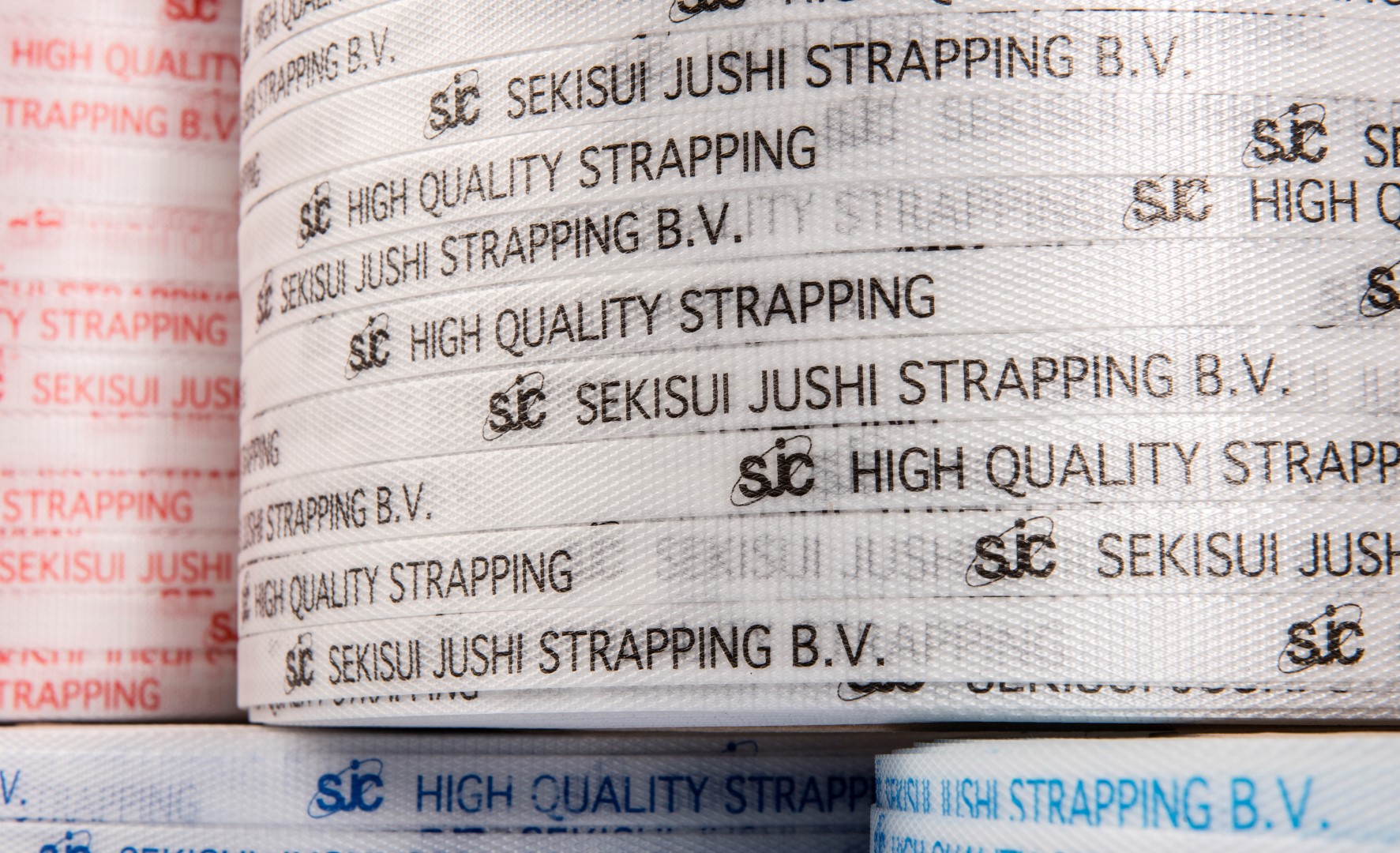

The strapping is smooth and even at this point. At this stage of the manufacturing process, the strapping is printed…

… and then immediately embossed. Subsequently, the strapping is wound onto coils.

To complete the manufacturing process, the coils are packed into boxes and loaded onto pallets.